SILO-SOLVE FC

SILO-SOLVE FC

Couldn't load pickup availability

As the daylight hours draw in, and the prospect of winter milk production where costs rapidly outpace income, becomes our new reality, the siren calls have already started. "more milk from forage"..."more milk from whole-crop cereals"..."less purchased feed"..."extended grazing"... "Aaah, we've heard and seen it all before, but there's one very good, and simple reason, why most dairy farmers end up back at the compound feed trough, and it is that home produced production is only possible with healthy soil, and healthy crops.

To quote the head of one of the UK's leading test labs: "Over 65% of the soil samples we receive are biologically dead". The knock-on effect of that, is that the crops they produce are predominantly "empty calories". So "more milk from forage" requires a lot more thought and positive remedial action, than simply wishing it to be so.

What goes wrong?

It's yeasts and moulds. In one of those horrible, undeserved, dilemmas, the better the farm makes the silage, the more likely it is to suffer from aerobic deterioration (heating, composting, silage). Modern silages are far more susceptible to aerobic instability, simply because they are predominantly made to produce high levels of lactic acid - and yet, in silage making, this ignores the pellicle yeasts (that contaminate the top of the plant), which have a high respiration capacity for lactic acid. These yeasts grow in a pH range of 3 - 8, so no amount of lactic acid will inhibit them, they can change the substrate they grow on, so not only can they withstand organic acids, they can grow on them, not only whilst some oxygen is present, but in the presence of sugar, even in anaerobic conditions. That generates heat, which then creates the ideal conditions for the development of moulds, other microbial pathogens, and the toxins they create.

Predisposing a silage to a fermentation that is very strongly biased towards lactic acid, may be the worst thing to do, as it will increase the opportunities for yeast and other pathogens to lower the feed value, and in many cases, produce a silage which is both harmful and unpalatable to the cows.

So even as we watch more farmers produce grass silages which are increasing the likelihood of physical and economic losses, the demand for whole-crop, maize silages, and even a return to arable silages, will become the "...more milk from not a lot".

Magnificent silage management helps greatly - in fact, it's the best solution, not only in making the silage correctly, but how the clamp/pit is treated at feed-out. Spending three weeks going across a wide silage face, during warm, muggy, periods, is almost guaranteed to generate significant yeast damage.

Now, at last, we see a solution to the problem, thanks to Danish BioTech giants (in both human and animal nutrition), Christian Hansen AS.

Not evolution, but revolution, as Hansens researchers combed through hundreds of thousands of naturally occurring bacteria, to identify unique properties in micro-organisms, and micro-organisms which had a synergy in what they would do in silage. One particular organism, Lactococcus Lactis O2.24 is an oxygen scavenger, which brings a completely new form of inhibitory mechanism to controlling yeasts in silage. When paired with an Acetic Acid producing organism Lactobacillus Buchneri CCM1819, this combination rapidly removes oxygen, and creates a balanced organic acid preservation with lactic and acetic acids.

INTRODUCING SILO-SOLVE

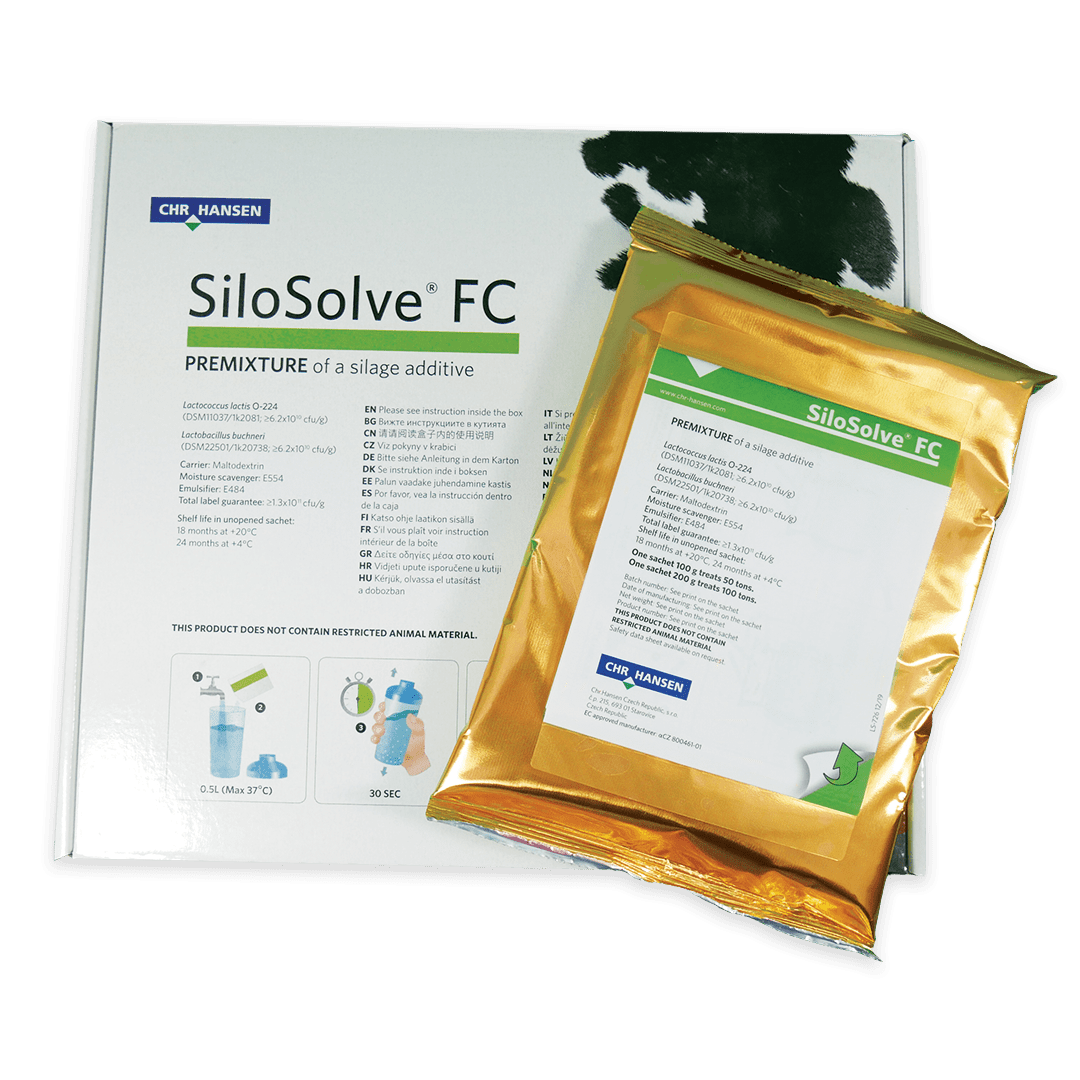

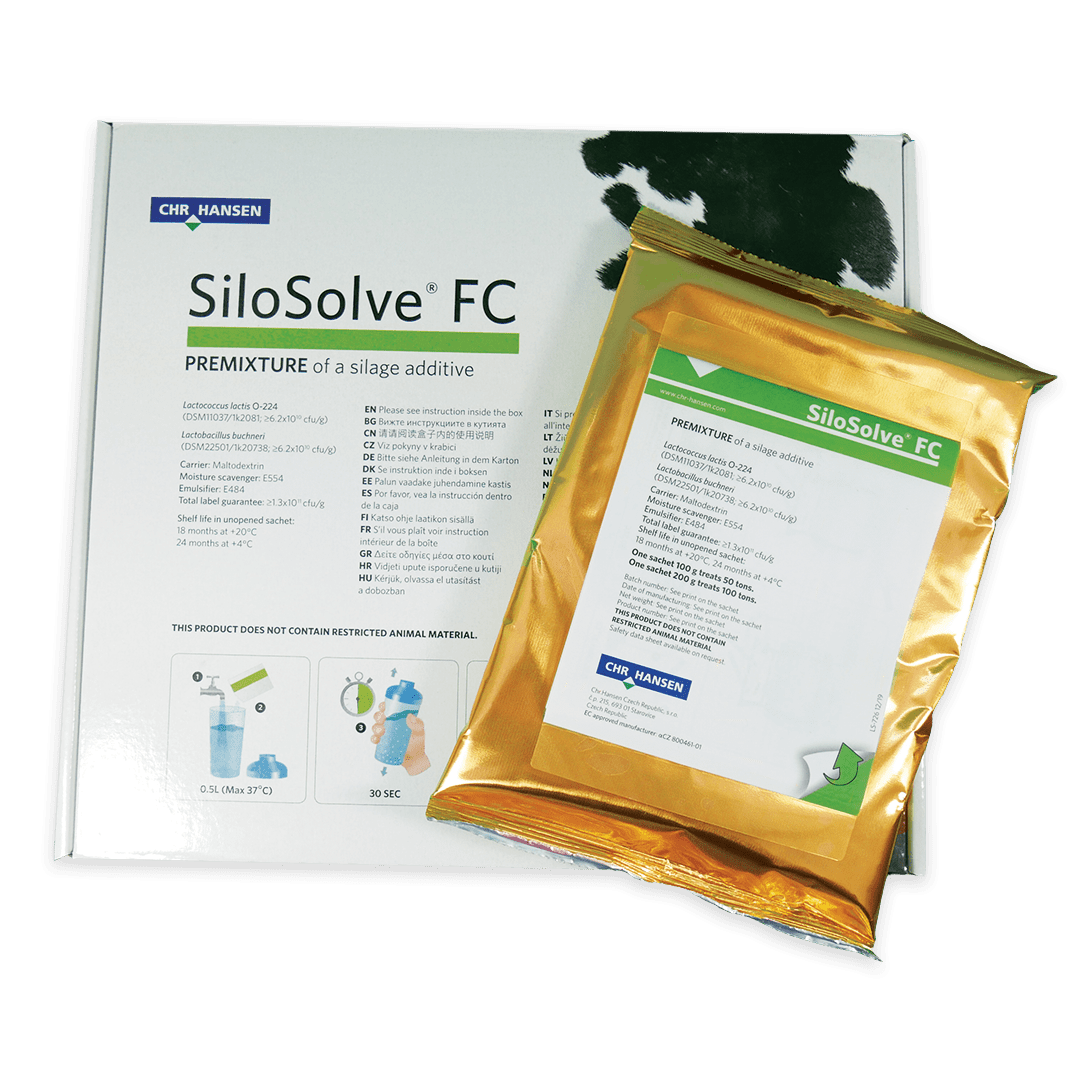

SiloSolve® is the latest concept from Chr. Hansen, and its worldwide rollout has received an excellent reception. Chr. Hansen's global reputation for innovation and technology is well demonstrated in their latest range of products.

With new developed, strains of bacteria with patented modes of action, SiloSolve is a completely new approach to silage making and is already well-proven to improve feed quality and secure a return-on-investment for farmers. The SiloSolve products have been specifically designed to stabilise, protect, and ferment silage.

SiloSolve can enhance the preservation of both high and low dry matter crops, control undesirable microorganisms, and improve overall animal performance. SiloSolve has been developed for functionality to meet the varying conditions of modern forage preservation.

SILO-SOLVE FC

"The jewel in the crown" - This is the newest product in the range, with which we have seen some of the most profound results in terms of stability in the most adverse conditions. Featuring the new, patented strain, Lactococcus lactis 0-224, which rapidly removes oxygen from the clamp in the early stages of fermentation, allowing an extremely fast stabilisation of the silage. This works synergistically with Lactobacillus buchneri to give an enhanced long term stability, reduced heating and inhibition of yeasts and moulds.

THE SILAGE CHALLENGE

THE GREAT SILAGE CHALLENGE: SILOSOLVE® FC VS. MOLD, YEAST AND THE COMPETITION

A stunning time-lapse video showing how silage treated SiloSolve FC compares to an untreated control and two silage samples treated with competing products.

For more information on this marvellous product Silo-Solve FC please call Gareth at the office on 01948 661602.

Mixing Instructions

Christian Hansen AS

"Improving food & Health" - the fundamental goal that drives Denmark based Chr. Hansen. They are a global supplier of bioscience based ingredients to the food, health and animal feed industries. With leading positions in the markets in which they operate, Chr. Hansen are a producer of cultures and dairy enzymes, probiotics and natural colours. The foundations of this success are product innovation and application, production processes, long-term customer relationships and intellectual property.

"Unknown but everywhere" Chr. Hansen is a very special kind of company. Virtually unknown outside their specialised field, yet several hundred million people around the world enjoy their products every day in the foods they eat. In fact, there's a good chance that you already had a bite of Chr. Hansen this morning. Perhaps you enjoyed deliciously creamy yoghurt, mouth-watering Italian style salami or a cheese with a distinct bite? Inevitably you are likely to have already enjoyed the benefits of Chr. Hansen’s technology and products without even knowing it!

Benefits

- It's possible to open the silage pits much earlier.

- The nutritive quality of the silage is better

- The stability once the pit is open is much better.

- Better intakes

- More quality milk

- Better profits from forage

- Can be used on all forages

Recommended feeding

(per head / day)

Disclaimer

Feeding rates are estimates, and other factors, such as animal health and environment, can have a greater impact on how animals perform. There is no guarantee that animals will perform as expected if fed the suggested rates. Rations should be balanced to provide enough energy and protein for animals, and they should include enough forage to keep the rumen healthy. Animals also need access to fresh water at all times.

- Choosing a selection results in a full page refresh.

- Opens in a new window.